On some makers there's a whole servo system in position that makes this whole procedure exceptionally fluid as well as specific. A machine controller sends out a signal via a motherboard to a servo electric motor, which links to each machine axis. The servo electric motor revolves a sphere screw that's affixed to the table on your CNC maker, making it relocate.

Much we have actually spoken concerning exactly how a CNC equipment uses its inner coordinate system. When your CNC locates its house placement, it's commonly at extreme mechanical constraints along the X, Y, as well as Z axes.

Selecting a beginning factor for your WCS needs some careful planning. Maintain these factors in mind when experiencing the process: The beginning will require to be discovered by mechanical methods with a side finder or probe, Repeatable origins assist in saving time when swapping out components, The origin needs to account for the needed resistances of downstream procedures There can be an additional full blog on picking one of the most ideal beginning point, particularly for each succeeding setup as the resistance stack-up begins to expand.

As we mentioned above, human operators will certainly utilize a WCS, which supplies an easy collection of works with for writing a CNC program. These coordinates are constantly different from a machine's collaborates, so how does your CNC device line the 2 up? With offsets. A CNC machine will utilize a job offset to identify the distinction in distance between your WCS and its very own residence placement.

The Basic Principles Of Cnc Milling Machine

If you are machining several components in one work, each part can be designated its very own countered. This enables the CNC maker to properly connect its coordinate system to several components in different areas as well as complete numerous configurations at once.

Programs tool offsets right into your CNC maker make this easy work. With a tool offset configured, your CNC machine will understand specifically just how much each device prolongs from the spindle. There are a number of methods to videotape a device countered:. Move the tool from the equipment's house setting to the component's no position.

Set all tools to a typical Z position at the top of a 1-2-3 precision block resting on the machine's table. Use a probe to determine the device offset automatically.

The left component of the face sits versus a Vise Stop. This establishes a repeatable X-axis beginning. Considering that one of the vice jaws is repaired, we can use this jaw to establish a repeatable Y-axis beginning, locating this place with the help of a side finder or probe. With our WCS in area, our maker currently understands the stock setting relative to its very own inner collaborates.

Everything about Cnc Laser

Now the component has actually to be turned over to deal with the opposite. Given that we simply turned the part 180 degrees, the external shape was symmetric, as well as the previous X and also Y offsets were repeatable, the WCS will certainly not change. We are also making use of the same tool to make sure that the same Z countered can be made use of.

If you haven't already seen it in your store, machinists will usually mark the closed setting of a vice with a black pen or use a torque wrench. Why are they doing this? To produce a constant securing pressure when relocating or rotating parts. Modifications in securing pressure can cause differences in the positioning of a component or other failings like part contortion or bowing, relying on part geometry.

Now we need to drill some holes, which requires standing the component on its end. This rotation doesn't change the XY-origin of the WCS. We now have a much shorter traveling range between our tool and part. This calls for a new balanced out to be made use of, which will shift the beginning indicate the top corner of the component.

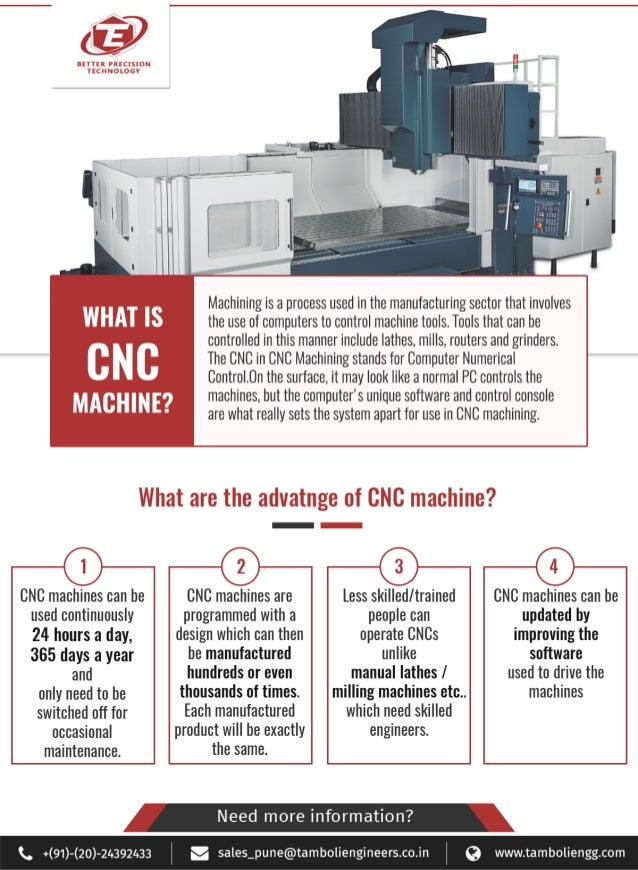

Humankind has actually consistently demonstrated our capacity to do and invent remarkable things utilizing just our hands as well as straightforward tools, yet the best creation by much has actually been available in the last half century when we created computers. Computers have the power to command and also control other devices with an accuracy that was prior to unthinkable.

The Single Strategy To Use For Cnc Machine

: "CNC Machining is a process made use of in the production industry that entails the usage of computers to control machine devices. Tools that can be regulated in this fashion include turrets, mills, routers and also mills.

: The patterns of motion a CNC device complies with are figured out by the instruction code configured in the usual CNC language g-code. G-code interacts the complete procedure for a machining procedure, consisting of rate, feed rate, as well as full variety of motion.: The CNC machining procedure is also directed in varying ways depending on whether it runs on a closed-loop or an open-loop system.

When shut, the control receives continuous feedback from an intermittent loop. While a CNC equipment can operate either system, a closed-loop might be more effective in fixing mistakes in the machining procedure as it obtains responses info on speed, energy, and position.: At BTM, we make use of several kinds of machining tools for an extensive manufacture technique to producing any kind of provided component.