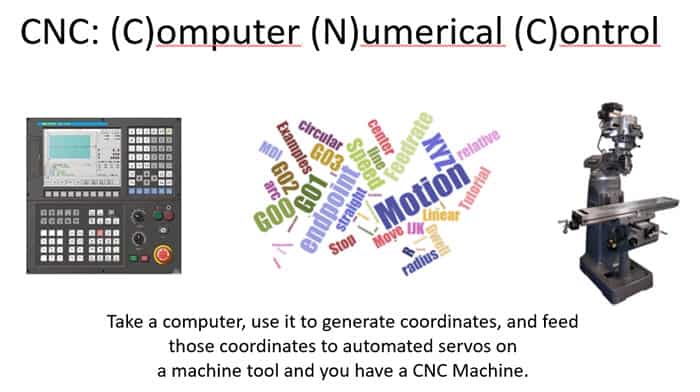

To the sightseer, a CNC system could appear like a routine set of computer system elements, but the software application and also gaming consoles utilized in CNC machining differentiate it from all various other kinds of calculation. If you want making use of CNC manufacturing to generate numerous products, discover more about just how CNC machining as well as CNC shows functions.

Any given workpiece can require a range of machine devices, such as drills as well as cutters. In order to suit these demands, a number of today's machines incorporate several various functions into one cell. At the same time, an installment might contain several makers and a collection of robot hands that move parts from one application to one more, however with everything controlled by the exact same program.

Turrets In turret machines, items are cut in a round direction with indexable devices. CNC turrets are used to create complex layouts that wouldn't be feasible on by hand run versions of the device.

However, most CNC lathes include 2 axes X and also Z. Plasma Cutters In a plasma cutter, a plasma lantern cuts the material. The procedure is primary put on steel materials but can likewise be utilized on other surfaces. In order to create the rate and also heat required to reduce metal, plasma is created with a combination of compressed-air gas and electric arcs.

With EDM, present discharges take place between 2 electrodes, and also this removes areas of a provided work surface. This makes it feasible for a current to pass between the two electrodes.

The 5-Second Trick For Cnc Lathe

In many cases, the water is blended with sand or a few other strong rough material. Business typically form factory maker components with this procedure. Water jets are employed as a cooler option for products that are unable to bear the heat-intensive procedures of various other CNC devices. As a result of their cooler nature, a number of industries like the aerospace and mining sectors depend on water jets, where they utilize them for carving and reducing, among various other functions.

What Else Can a CNC Equipment Do? As lots of CNC device video clip presentations have revealed, business use CNC equipments to make highly outlined cuts out of steel pieces for commercial equipment products. Along with the aforementioned equipments, you can discover several other usual pieces of equipment used in CNC manufacturing to produce very detailed and exact CNC items.

This post will certainly go over the most common kinds: lathes as well as milling makers. History, Although wood-working lathes have been in usage given that Biblical times, the initial functional metalworking turret was created in 1800 by Henry Maudslay. It was simply a device tool that held the piece of product being functioned, or workpiece, in a clamp, or spindle, as well as turned it so a cutting device might device the surface to the wanted shape.

Dimensional precision was regulated by the operator who observed the finished dials on the handwheels as well as relocated the reducing device the suitable amount. Each component that was generated required the driver to repeat the motions in the same sequence and to the same measurements. The initial milling equipment was run in similar fashion, other than the reducing device was placed in the revolving spindle.

The motions that are utilized in equipment tools are called "axis," and are referred to as "X" (typically left to right), "Y" (normally front to back), and "Z" (up as well as down). The work-table may also be rotated in the horizontal or upright airplane, creating a fourth axis of movement.

Cnc Mill Fundamentals Explained

Among the problems with these early devices was that they required the operator to control the handwheels to make each part. Besides being dull and also physically tiring job, the ability of the operator to make the same components was restricted. Small distinctions in procedure led to variant of the axis measurements, which, in turn, produced inadequately suitable or unusable parts.

As manufacturing amounts raised, the number of functional parts produced per driver each day were no much longer affordable. What was needed was a way to run the motions of the maker immediately. Early tries to "automate" these operations utilized a series of web cams that moved the tools or worktable via linkages.