Making use of a computer card reader and specific servomotor controls, the resulting device was significant, difficult, and costly. It worked automatically, however, as well as produced items with the high level of precision needed by the aircraft industry. By the 1960s, the cost and also complexity of automated machines had been reduced to the point where they found applications in various other sectors.

The electric motors took electric instructions from a tape viewers, which checked out a paper tape roughly 1 in (2. 5 centimeters) in width that was punched with a select collection of holes. The setting and series of the openings allowed the visitor to create the necessary electrical impulses to turn the motors at just the specific time as well as price, which basically operated the maker just like the human driver.

These were usually called "NC," or Numerical Regulated machines. A programmer generated the tape on a typewriter-like machine, just like the old "punch cards" used in very early computer systems, which functioned as the "program." The size of the program was established by the feet of tape required to be reviewed to create a specific part.

He asked the International Organization Machine Corp. to permit him to make use of among their primary frame office computer systems to make a series of computations for a brand-new helicopter blade. At some point, Parsons made a setup with Thomas J. Watson, the epic head of state of IBM, where IBM would deal with the Parsons Firm to produce an equipment controlled by punched cards.

Indicators on Cnc You Should Know

With advances in integrated electronics, the tape was gotten rid of, or used just to pack the program right into magnetic memory. The capability of the memory of contemporary CNC devices is still often referred to as "feet of memory."The modern CNC device functions by reading the thousands of little bits of info stored in the program computer memory.

The program may contain "code" commands, such as "M03" which instructs the controller to relocate the pin to a new position, or "G99," which advises the controller to check out an auxiliary input from some process inside the maker. Code commands are one of the most common means to set a CNC device tool.

In conversational shows, the "M03" command is entered merely as "STEP," and the "G99" command is merely "READ." This sort of programs enables quicker training as well as much less memorizing of the code definitions by the programmers. It is important to keep in mind, nevertheless, that most conversational devices still read code programs, because the industry depends on that form of programming rather heavily.

In some equipments, as an example, the designer can merely type in the location, diameter, and deepness of a function and also the computer will certainly pick the best machining method for producing the attribute in the workpiece. The most recent equipment can take a computer-generated engineering version; determine the proper device rates, feeds, and courses; as well as produce the component without an illustration or program ever being created.

An Unbiased View of Wood Cnc Machine

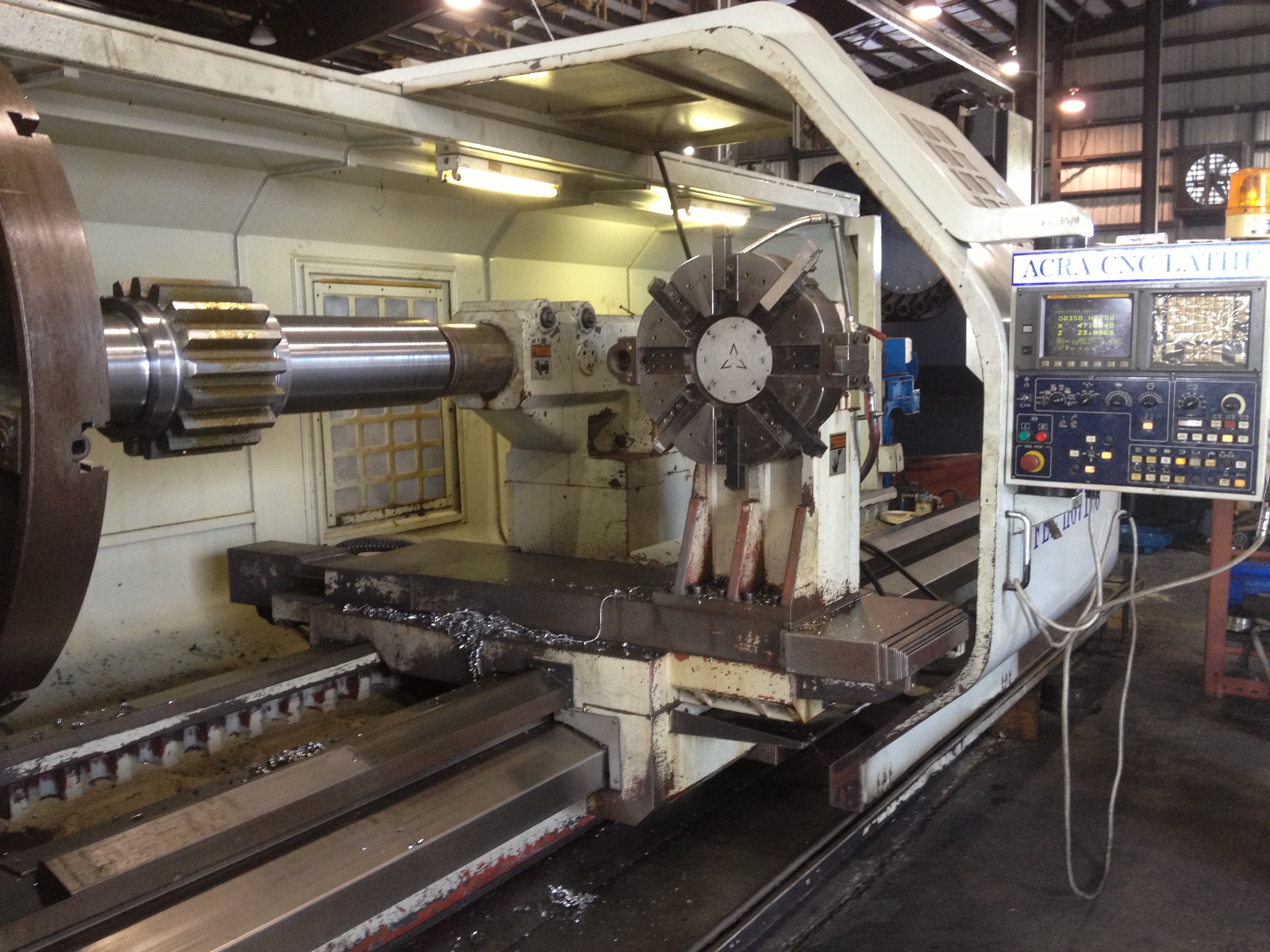

The pin is typically the toughest component as well as is sustained by huge bearings. Whether the pin holds the job or the tool, an automated securing function permits the spindle to rapidly secure and unclamp during the program run. Connected to the side of the maker is a magazine of different devices.

Typical cycle time needed for this treatment is 2 to eight secs. Some machines might contain approximately 400 devices in large "hives," each automatically loaded in series as the program runs. The bed or worktable of the machine is supported on set steel "methods" which are usually protected by adaptable guards.

Today, many machines make liberal usage of weldments of hot-rolled steel and wrought items such as stainless-steel to minimize cost and enable fabrication of more complex frame layouts. Some equipments are designed as cells, which implies they have a certain group of parts they are created to manufacture. Cell devices have huge tool publications to bring sufficient devices to do every one of the various operations on each of the various components, large worktables or the ability to change worktables, and also special stipulations in the controller for information inputs from other CNC equipments.

A team of cells, some containing 20 or 30 equipments, is called a Flexible Machining System. These systems can create literally thousands of different parts at the exact same time with little human intervention. Some are designed to run day and night without supervision in what is referred to as "lights out" manufacturing.

Cnc Laser Things To Know Before You Get This

Currently, standardized tooling design has actually allowed devices to be developed for stock or later sale, because the brand-new styles can perform all the needed procedures of a lot of customers. The cost of a new CNC maker ranges from concerning $50,000 for a vertical center to $5 million for a Flexible Machining System for engine blocks.