The part turns around the device. This process is frequently utilized for round parts. You can produce the very same parts using a milling device as you can with a turret, however the process for creating cylindrical parts as well as various other parts that prefer this kind of maker is a lot more streamlined using a turret.

CNC machines can produce consistent components, rapidly. Not only can they outpace their conventional counterparts, CNC machines can work around the clock, never requiring a break, other than for regular upkeep.

CNC machining equipment can follow the very same sets of directions over and also over once more to promote little or large production runs of the same items. CNC machines can be found in several ranges as well as levels of complexity. Some equipments can hold numerous tools at the time or work along X, Y, as well as Z axes to eliminate excess product from any type of side or at any type of angle.

These systems both instruct the cutting as well as forming devices that eliminate, however CNC machining devices can adhere to facility, tailored sets of guidelines that originate from complicated CAD or web cam styles. Different CNC machining equipment can deal with different tools, capabilities, and operations. The CNC machining procedure commonly includes these basic steps: 1.

2. Transforming CAD Documents to Usable CNC Directions Once the design is total, the layout specifications need to be converted right into instructions that CNC equipments can adhere to. The CAD documents are gone through computer-aided manufacturing (CAMERA) software application. These programs develop the programs code that CNC machines make use of to route the tools during the manufacturing procedure.

The smart Trick of Cnc Wood Router That Nobody is Discussing

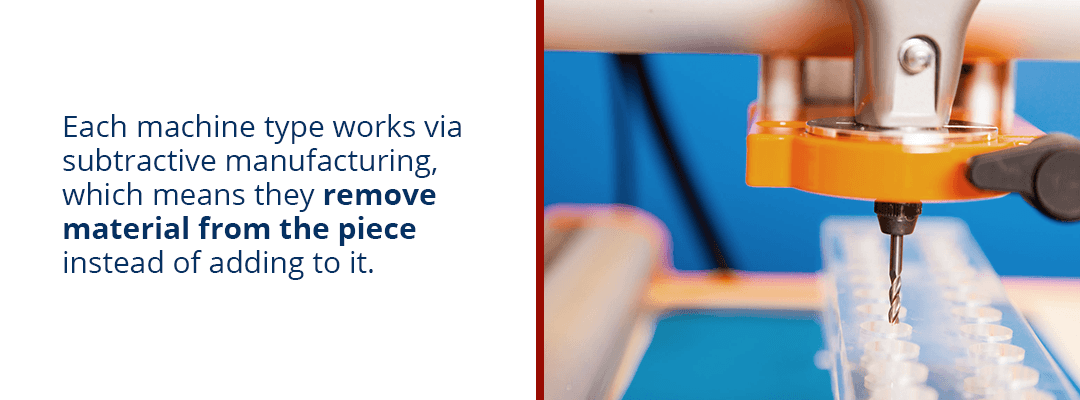

Kinds of CNC Machining Procedures CNC machining is a very wide category of possible procedures and processes. Among CNC machining procedures, exploration, milling, as well as turning are the most usual.

When the work surface is pressed against milling devices, thin strips or cuts of product are gotten rid of from the existing side. This can develop shallow cuts, broad cuts, or flat-bottom cavities to shape the part. Peripheral milling processes might reduce much deeper to produce slots or threads right into the item's general shape.

They consist of reducing processes such as monotonous, grooving, as well as dealing with. They cut excess product off of a work surface by using single-point cutting devices exactly put on the rotating work surface. Transforming creates round components that have actually a specified size. Transforming can produce direct attributes both inside and also on the exterior side of the parts.

CNC machining can also create components with elaborate, complicated designs. Every CNC machining process starts with a CAD design, so the prototyping procedure will be much quicker.

To read more concerning all of our manufacturing abilities, or to ask for a quote, contact us straight.

Top Guidelines Of Cnc Laser Cutting Machine

What Is CNC Machining? It's crucial to ace the mold and mildew tool layout process. The greater the precision and also mass-production required, the more intricate the tooling can become. Producers create this high level of accuracy using computer system numerical control (CNC), replacing by hand run makers, upright millers, and also turrets with a central, automatic system.