The part revolves around the device. This procedure is commonly made use of for round parts. You can produce the exact same components making use of a milling maker as you can with a turret, but the procedure for creating cylindrical components as well as various other components that prefer this type of machine is a lot more streamlined using a lathe.

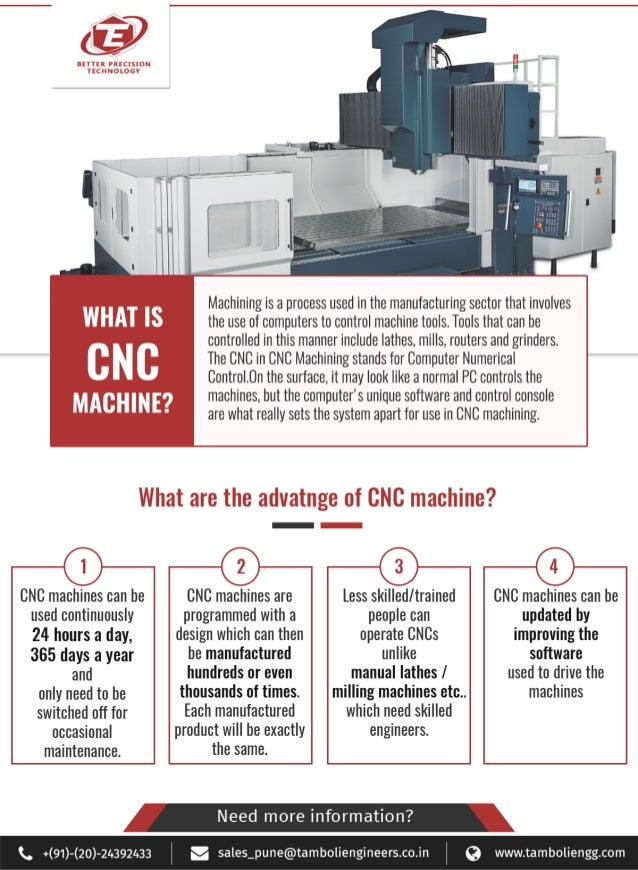

CNC equipments can produce uniform components, quickly. Not just can they outpace their conventional counterparts, CNC makers can function around the clock, never needing a break, other than for routine upkeep.

CNC machining equipment can follow the very same collections of directions over and also over once again to promote small or huge manufacturing runs of the same items. CNC equipments are available in multiple varieties and degrees of complexity. Some makers can hold numerous tools at the time or job along X, Y, and Z axes to get rid of excess material from any kind of side or at any angle.

These systems both instruct the cutting as well as creating devices that remove, however CNC machining equipment can adhere to complicated, tailored sets of directions that come from complex CAD or CAM layouts. Various CNC machining tools can take care of various tools, capabilities, and also operations. The CNC machining process generally includes these basic actions: 1.

Transforming CAD Files to Usable CNC Guidelines Once the style is complete, the layout requirements need to be equated into directions that CNC equipments can adhere to. These programs produce the programs code that CNC machines make use of to route the tools throughout the production procedure.

What Does Cnc Plasma Mean?

Types of CNC Machining Operations CNC machining is a very broad category of feasible operations and procedures. Amongst CNC machining procedures, boring, milling, and also transforming are the most common.

When the work surface is pushed versus milling devices, slim strips or cuts of product are gotten rid of from the existing edge. This can create superficial cuts, large cuts, or flat-bottom tooth cavities to form the part. Peripheral milling processes might cut much deeper to create slots or threads right into the item's general form.

They cut excess material off of a work surface by utilizing single-point cutting tools exactly applied to the turning workpiece. Turning can create direct functions both inside and on the exterior edge of the components.

The machines comply with these instructions without enabling any type of unwanted variation or human mistake. The parts will be top quality, exact, as well as identical. CNC machining can additionally generate components with detailed, complex styles. Every CNC machining procedure begins with a CAD layout, so the prototyping procedure will certainly be much faster. The software program catches or stops several possible style imperfections or possible dangers with different products.

For more information regarding all of our production capabilities, or to ask for a quote, call us straight.

Things about Cnc Laser Cutting Machine

What Is CNC Machining? It's vital to ace the mold device style process. The higher the accuracy and also mass-production required, the much more complicated the tooling can come to be. Suppliers develop this high degree of accuracy making use of computer numerical control (CNC), replacing manually operated equipments, upright millers, and also lathes with a centralized, automated system.