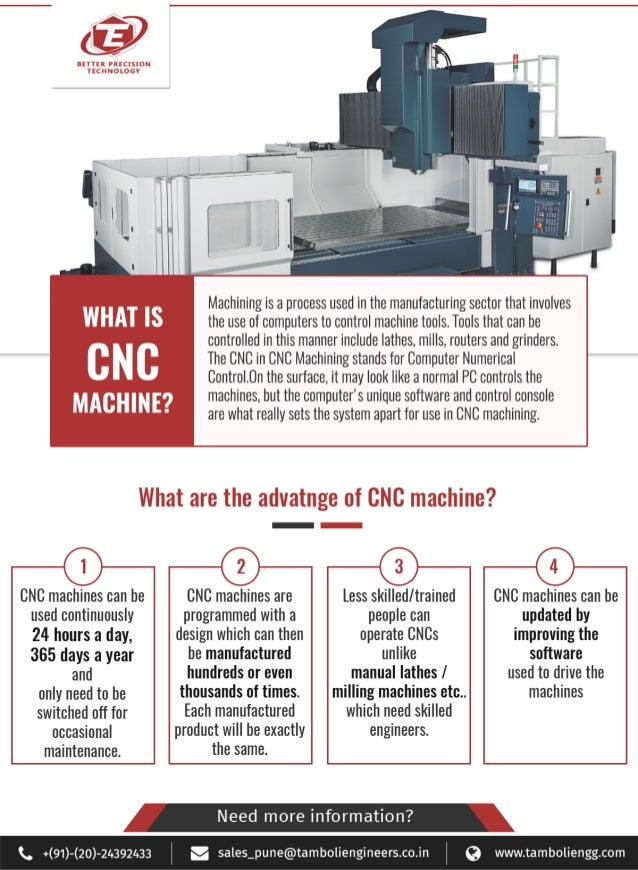

To the observer, a CNC system could look like a routine set of computer components, however the software application programs as well as gaming consoles used in CNC machining distinguish it from all various other types of calculation. If you have an interest in making use of CNC manufacturing to create different items, figure out more about how CNC machining and CNC programming functions.

Any given workpiece could require a variety of equipment tools, such as drills and also cutters. In order to suit these requirements, much of today's equipments incorporate numerous various features right into one cell. At the same time, an installation may contain several makers and also a collection of robotic hands that move components from one application to one more, but with everything managed by the same program.

Turrets In lathe equipments, items are cut in a round direction with indexable devices. CNC turrets are made use of to create complex designs that wouldn't be feasible on manually run versions of the machine.

Nonetheless, most CNC lathes include two axes X and Z. Plasma Cutters In a plasma cutter, a plasma lantern reduces the material. The process is primary put on metal materials however can additionally be utilized on various other surfaces. In order to produce the speed and also warm required to cut steel, plasma is generated via a mix of compressed-air gas as well as electrical arcs.

With EDM, present discharges occur in between two electrodes, and this eliminates sections of an offered workpiece. When the room between the electrodes comes to be smaller sized, the electric area ends up being a lot more extreme and therefore stronger than the dielectric. This makes it feasible for an existing to pass between both electrodes. Sections of a work surface are gotten rid of by each electrode.

8 Easy Facts About Cnc Cutting Shown

Firms commonly form manufacturing facility equipment components via this process. Water jets are used as a cooler option for materials that are incapable to birth the heat-intensive procedures of various other CNC equipments.

What Else Can a CNC Maker Do? As lots of CNC device video clip presentations have shown, business use CNC devices to make extremely described remove of steel pieces for commercial hardware products. In enhancement to the previously mentioned devices, you can discover numerous other usual pieces of equipment utilized in CNC making to produce very outlined and also precise CNC products.

This article will review the most typical kinds: lathes and also milling makers. History, Although wood-working lathes have been in use because Scriptural times, the very first sensible metalworking turret was created in 1800 by Henry Maudslay.

Dimensional accuracy was regulated by the operator that observed the finished dials on the handwheels as well as relocated the cutting device the appropriate amount. Each part that was created needed the driver to repeat the movements in the very same series as well as to the same dimensions. The very first milling maker was run in similar way, other than the cutting tool was positioned in the rotating spindle.

The movements that are made use of in device tools are called "axis," as well as are referred to as "X" (typically left to right), "Y" (normally front to back), and also "Z" (up and down). The work-table might additionally be turned in the straight or upright plane, producing a 4th axis of activity.

Cnc Laser Cutting Machine – Truths

Among the issues with these very early machines was that they required the driver to control the handwheels to make each part. Besides being boring as well as physically tiring job, the capacity of the operator to make similar components was restricted. Small distinctions in procedure resulted in variant of the axis measurements, which, in turn, developed badly fitting or unusable components.

As manufacturing amounts increased, the variety of functional parts produced per driver each day were no much longer affordable. What was required was a method to run the activities of the machine instantly. Early tries to "automate" these operations utilized a series of cams that relocated the devices or worktable via affiliations.