This sort of lathe equipment training can include programs on: Identifying where edits are required from comparing example parts to their specs CNC programs modifies Creating numerous cycles of test elements to improve the results of edits Regulating coolant flow, cleansing the lathe, and also repair service and substitute of devices Various other CNC Machining Procedures Various other mechanical CNC machining operations include: CNC Machining Devices and Parts As shown over, there is a large range of machining operations offered.

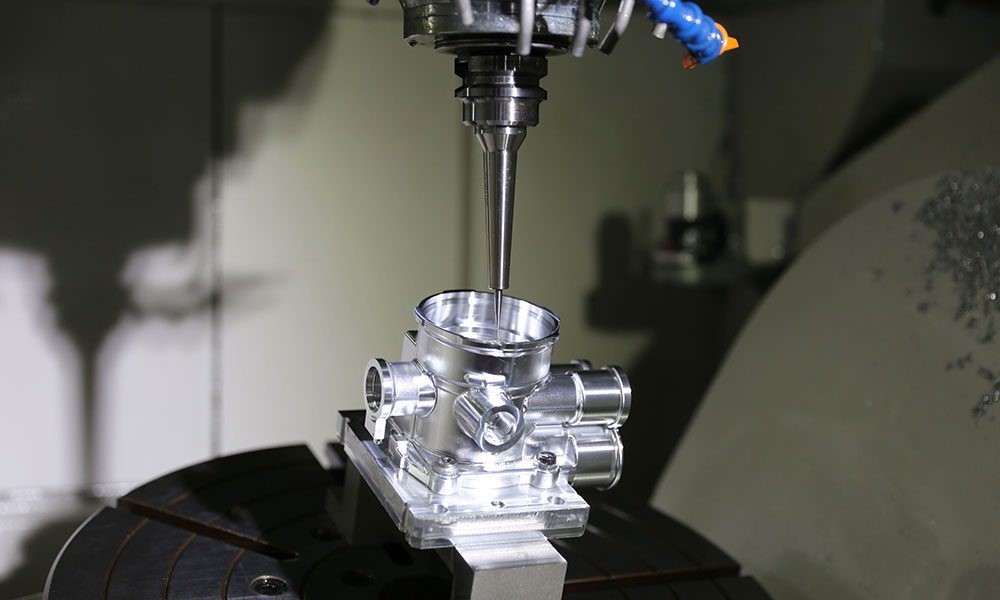

Some software applications have integrated every one of the facets of CAD, CAMERA, and CAE software. This integrated program, generally described as CAD/CAM/CAE software, permits a single software application to take care of the entire construction procedure from style to analysis to manufacturing. What is a CNC Equipment? Sorts Of CNC Machines as well as Maker Devices Depending on the machining operation being done, the CNC machining process utilizes a selection of CNC devices and also machine tools to generate the custom-designed part or item.

Table 1, below, details some of the difficulties of machining large parts as well as hefty components.

Have your CNC devices been acting unusually lately? What Is a CNC Equipment? In other words, controllers program the CNC machine to tell the equipment shop devices what to do.

The CNC device does this by telling the factory device precisely how to relocate, and specifically what pieces of the material to remove, to ultimately reach the preferred result. It has lots of similarities with 3D printing, in that a computer system products electronic instructions to tools that after that work to develop an ended up product.

Some Known Questions About Cnc Plasma.

They create troubles as well as need upkeep similar to any other type of maker or device. As well as like any other tool, there are specific points you can do that might accidentally harm these makers. There are likewise certain actions you can require to keep them in good functioning order. While there are definitely any type of number of troubles that can result in problems and errors within CNC machining, some issues are a lot more prevalent than others.

Let's check out a few of the most usual troubles in CNC devices. Poor or Improper Maintenance CNC machines need to be very carefully cleaned up as well as lubed often otherwise, troubles can begin to occur. An absence of cleaning could result in a buildup of dirt as well as particles. This could appear to be totally a health issue, yet it can have actual implications in the machine's outcome.

If this concern remains to go unattended, it will develop obstacles as the machine has a hard time to situate and hold materials still. This results in higher issues with precision and precision, and also eventually results in extra mistakes. Improper lubrication can result in device components sticking or otherwise moving as efficiently as they should.

Both getting too hot and also a lack of air can additionally trigger problems like material motion during the procedure. Incorrect Settings or Devices Perhaps among your devices is coming to be blunt, a cutting coolant or lubricant is falling short to function correctly or a tool is moving at the wrong speed. All these problems will trigger comparable sorts of problems.

The factor for this is simple. If the device is moving as well gradually, the product will certainly be under the reducing side for longer than it ought to be. This results in the burning and scarring you're seeing. Likewise, if the coolant is not working appropriately, points can be getting too warm, and also the sides of the material could be obtaining singed as an outcome.