To the onlooker, a CNC system may appear like a regular collection of computer system parts, yet the software program programs and gaming consoles utilized in CNC machining differentiate it from all other kinds of computation. If you want making use of CNC making to generate numerous items, locate out even more about just how CNC machining and also CNC programming works.

Any type of offered work surface can demand a range of machine devices, such as drills as well as cutters. In order to suit these requirements, many of today's makers incorporate several various functions into one cell. Alternately, a setup might include a number of machines and a set of robot hands that transfer parts from one application to an additional, however with everything controlled by the exact same program.

Turrets In lathe equipments, pieces are cut in a round instructions with indexable tools. CNC turrets are utilized to generate complicated layouts that wouldn't be possible on by hand run variations of the equipment.

However, most CNC lathes contain two axes X and also Z. Plasma Cutters In a plasma cutter, a plasma lantern cuts the product. The procedure is foremost related to steel products yet can additionally be employed on various other surfaces. In order to generate the rate as well as warmth needed to cut steel, plasma is generated through a combination of compressed-air gas as well as electric arcs.

With EDM, existing discharges happen between 2 electrodes, and this eliminates areas of a given workpiece. When the area between the electrodes diminishes, the electric area ends up being more extreme as well as hence more powerful than the dielectric. This makes it possible for a present to pass in between both electrodes. Subsequently, portions of a workpiece are eliminated by each electrode.

Some Known Facts About Cnc Plasma.

Sometimes, the water is combined with sand or a few other solid abrasive compound. Business often shape manufacturing facility device parts via this process. Water jets are employed as a cooler option for products that are not able to bear the heat-intensive processes of various other CNC devices. As a result of their cooler nature, a number of fields like the aerospace as well as mining industries count on water jets, where they utilize them for carving as well as cutting, to name a few features.

What Else Can a CNC Device Do? As lots of CNC maker video demonstrations have revealed, business make use of CNC devices to make very described cuts out of metal items for industrial hardware items. In addition to the previously mentioned machines, you can find numerous various other typical items of machinery made use of in CNC manufacturing to create very outlined as well as exact CNC products.

This article will certainly discuss the most usual types: lathes as well as milling devices. History, Although wood-working turrets have been in usage considering that Scriptural times, the first functional metalworking turret was developed in 1800 by Henry Maudslay.

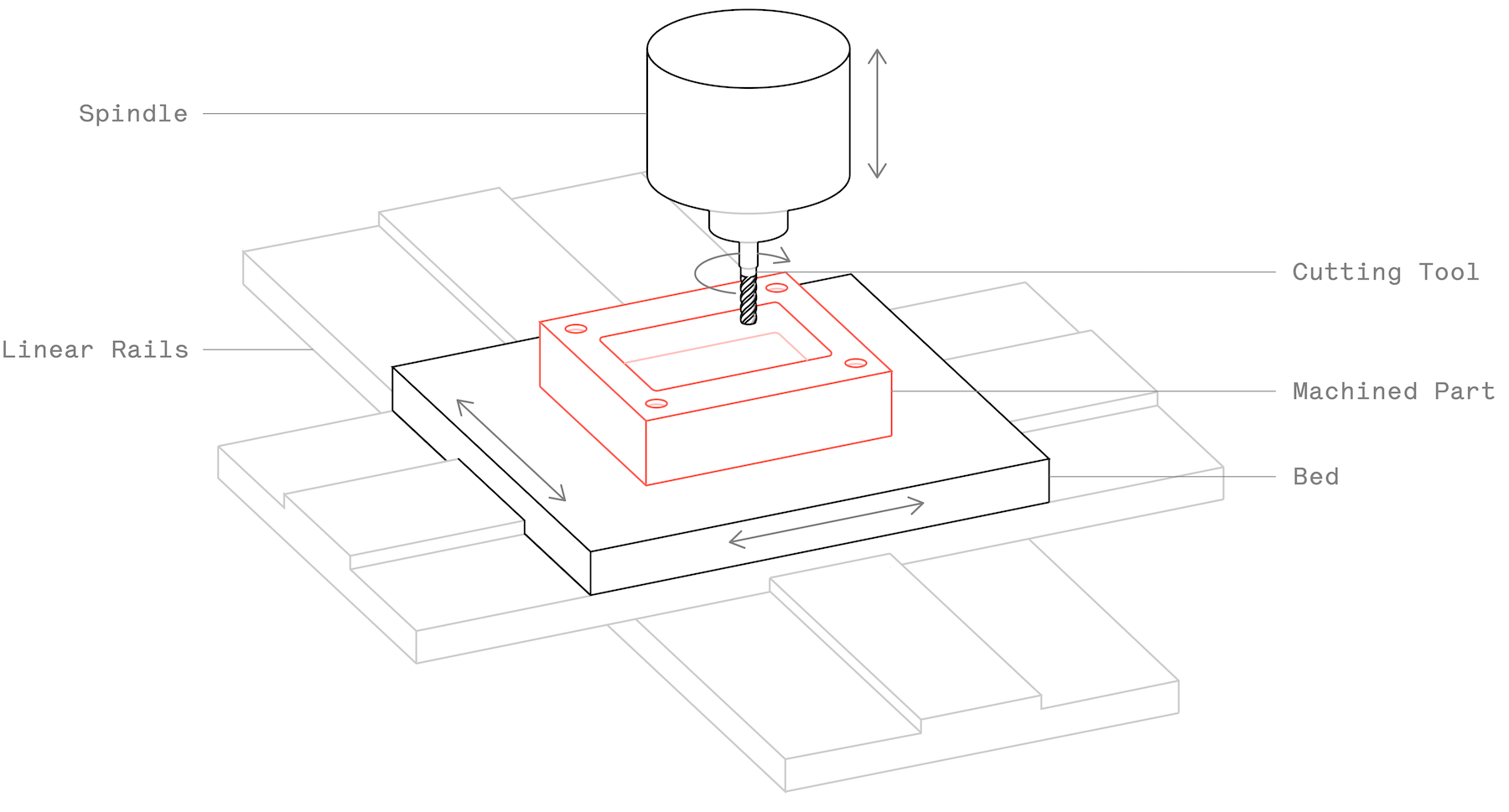

Dimensional accuracy was regulated by the operator that observed the graduated dials on the handwheels as well as relocated the reducing tool the suitable quantity. Each part that was produced needed the operator to duplicate the activities in the exact same series as well as to the same measurements. The first milling device was run in similar way, except the reducing device was put in the turning spindle.

The activities that are made use of in device tools are called "axis," as well as are referred to as "X" (usually left to right), "Y" (generally front to back), as well as "Z" (up as well as down). The work-table may additionally be rotated in the straight or vertical aircraft, creating a fourth axis of activity.

The 5-Second Trick For Cnc Router Machine

One of the problems with these very early makers was that they called for the operator to control the handwheels to make each component. Besides being monotonous as well as literally laborious work, the capability of the driver to make identical components was restricted. Small differences in operation caused variant of the axis dimensions, which, consequently, produced inadequately fitting or unusable parts.

As manufacturing quantities enhanced, the variety of useful parts produced per operator each day were no longer affordable. What was required was a means to run the movements of the device instantly. Early tries to "automate" these procedures made use of a collection of webcams that moved the tools or worktable via linkages.