This type of lathe device training can include programs on: Identifying where edits are required from comparing example parts to their specs CNC programs modifies Creating several cycles of test parts to refine the outcomes of edits Controling coolant flow, cleaning the turret, and repair service and substitute of devices Other CNC Machining Procedures Other mechanical CNC machining procedures consist of: CNC Machining Devices as well as Parts As indicated over, there is a large range of machining operations readily available.

Some software application applications have actually incorporated all of the facets of CAD, CAMERA, and also CAE software. This integrated program, usually referred to as CAD/CAM/CAE software application, enables a single software program to manage the whole manufacture procedure from layout to evaluation to manufacturing. What is a CNC Equipment?

Table 1, below, describes some of the obstacles of machining big parts and hefty parts.

Have your CNC machines been acting oddly recently? Do you observe a strange tick in their output, or in the way the devices are acting? If so, you're in the right place. We're going to discuss a few of the most common issues in CNC machines, and how to repair these problems.

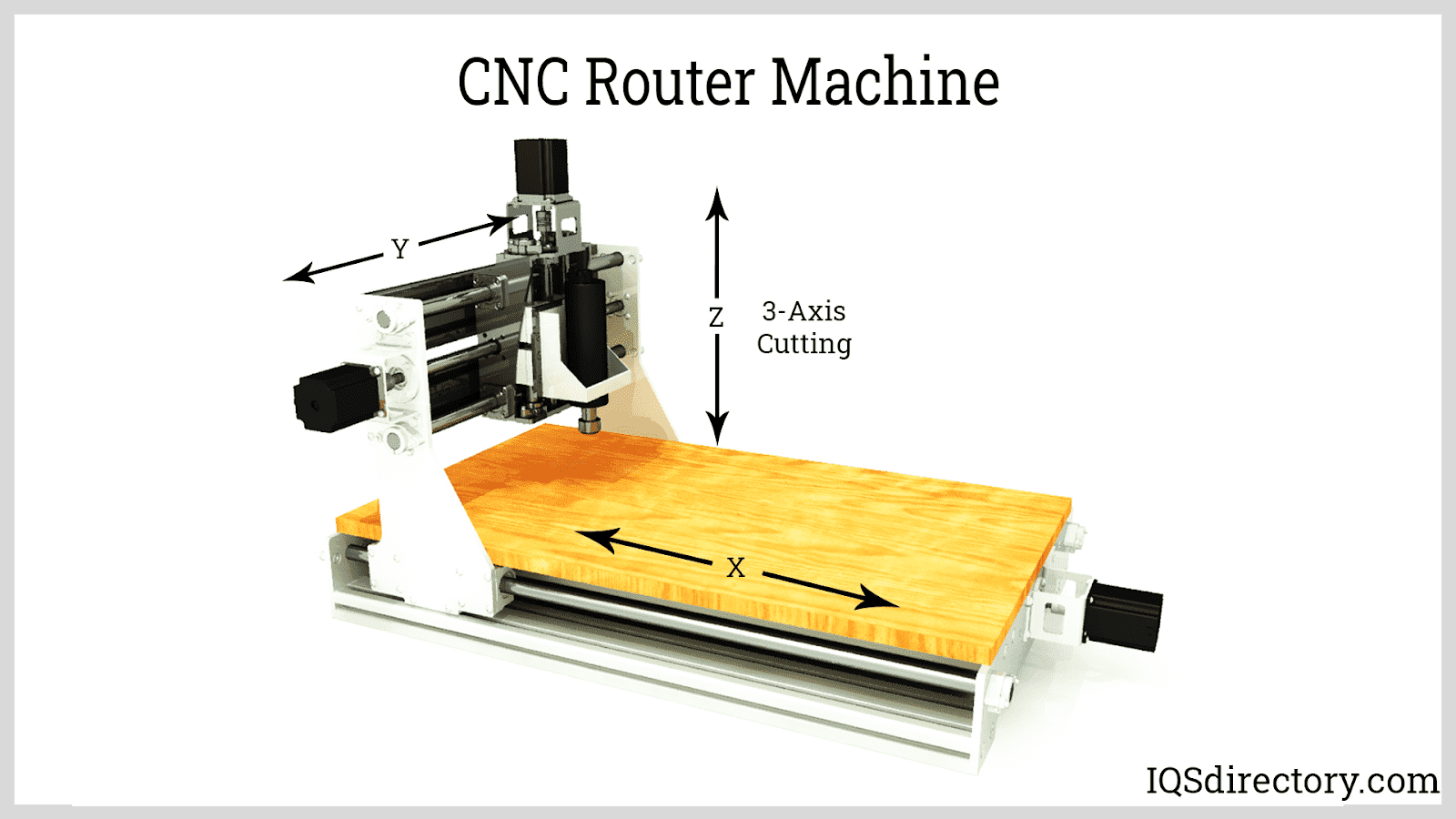

What Is a CNC Maker? Exactly How Does CNC Machining Job? What Causes Issues in CNC Machines? Fixing Tips What Is a CNC Equipment? A CNC equipment is an electro-mechanical tool made use of to control and control machine-shop devices and gadgets making use of computer system programs. To put it simply, controllers program the CNC maker to tell the device store tools what to do.

The CNC machine does this by telling the factory device specifically just how to relocate, and precisely what items of the material to cut away, to eventually come to the preferred result. It has numerous similarities with 3D printing, in that a computer system products electronic guidelines to tools that after that function to produce a finished item.

The Ultimate Guide To Cnc Cutting

They establish issues as well as need maintenance just like any kind of various other kind of equipment or device. And like any kind of various other device, there are certain points you can do that may unintentionally damage these equipments. There are also certain actions you can take to maintain them in great working order. While there are certainly any kind of variety of problems that can lead to concerns as well as errors within CNC machining, some issues are a lot more prevalent than others.

Let's consider a few of one of the most usual issues in CNC equipments. Poor or Improper Upkeep CNC equipments require to be thoroughly cleaned as well as lubed on a regular basis otherwise, problems can start to occur. A lack of cleansing might result in an accumulation of dust and particles. This could seem to be simply a hygiene issue, however it can have genuine ramifications in the maker's outcome.

If this concern remains to go unattended, it will produce difficulties as the equipment has a hard time to find and hold materials still. This results in greater problems with accuracy and also precision, as well as eventually results in extra mistakes. Improper lubrication can lead to equipment components sticking or otherwise relocating as smoothly as they should.

Both overheating and a lack of air can also trigger problems like material motion throughout the procedure. Improper Setups or Tools Probably among your tools is ending up being candid, a cutting coolant or lube is failing to function appropriately or a tool is moving at the wrong rate. All these issues will certainly trigger similar type of problems.

If the device is moving as well gradually, the product will certainly be under the reducing edge for longer than it ought to be. If the coolant is not functioning appropriately, points could be getting too warm, as well as the sides of the product could be obtaining singed as an outcome.