On some machines there's an entire servo system in area that makes this whole procedure extremely fluid and precise. An equipment controller sends a signal through a circuit board to a servo motor, which connects to each device axis.

0002 inches. Much we've spoken regarding how a CNC maker utilizes its internal coordinate system. The problem is, this coordinate system isn't extremely simple to recommendation by us people. When your CNC locates its house setting, it's normally at extreme mechanical restrictions along the X, Y, and also Z axes.

Choosing an origin factor for your WCS calls for some mindful planning. Maintain these factors in mind when undergoing the process: The origin will need to be located by mechanical means with an edge finder or probe, Repeatable beginnings conserve time when exchanging out parts, The beginning needs to make up the required resistances of downstream operations There can be an additional complete blog on choosing the most optimal beginning factor, particularly for each succeeding configuration as the tolerance stack-up starts to grow.

As we mentioned above, human drivers will use a WCS, which provides a very easy set of collaborates for composing a CNC program. Nonetheless, these collaborates are always various from a device's works with, so just how does your CNC equipment line both up? With offsets. A CNC equipment will certainly use a work countered to identify the difference in range between your WCS and its very own house position.

7 Easy Facts About Cnc Lathe Explained

Below we can see that several offsets are configured; G54, G55, and also G59. What's the advantage of having several offsets? If you are machining multiple components in one task, each component can be appointed its very own countered. This allows the CNC maker to accurately associate its coordinate system to several parts in various places and also total several setups at when.

Programs tool offsets right into your CNC maker make this simple work. With a tool balanced out configured, your CNC maker will certainly know exactly just how much each device expands from the spindle. There are several methods to tape a device offset:. Relocate the tool from the maker's home placement to the part's no position.

Establish all tools to an usual Z placement at the top of a 1-2-3 accuracy block relaxing on the device's table. Make use of a probe to figure out the device balanced out instantly.

The left part of the face sits against a Vise Stop. This establishes a repeatable X-axis beginning. Since one of the vice jaws is repaired, we can utilize this jaw to determine a repeatable Y-axis origin, finding this area with the help of a side finder or probe. With our WCS in position, our machine now understands the supply placement loved one to its very own interior works with.

The Only Guide for Cnc Plasma Cutter

Now the part needs to be turned over to deal with the opposite side. Since we simply flipped the component 180 levels, the outer shape was symmetric, as well as the previous X and also Y offsets were repeatable, the WCS will certainly not transform. We are additionally utilizing the same device to make sure that the very same Z offset can be made use of.

If you have not already seen it in your store, machinists will normally mark the shut position of a vice with a black marker or utilize a torque wrench. Why are they doing this? To create a consistent securing pressure when moving or rotating components. Changes in securing pressure can lead to differences in the positioning of a component or other failures like component contortion or bowing, relying on part geometry.

Currently we require to drill some openings, which requires standing the part on its end. This turning doesn't change the XY-origin of the WCS. We currently have a much shorter travel distance in between our tool and part. This calls for a new balanced out to be utilized, which will certainly move the beginning point to the leading corner of the part.

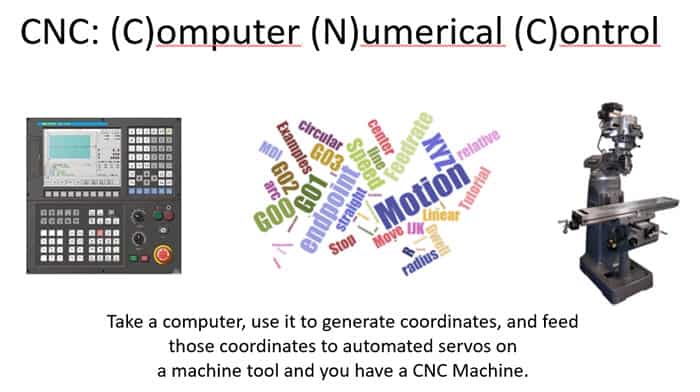

Mankind has actually constantly demonstrated our capacity to do as well as invent impressive things making use of just our hands as well as basic devices, yet the biggest development without a doubt has actually been available in the last half century when we established computer systems. Computers have the power to command and control other devices with an accuracy that was prior to unthinkable.

5 Simple Techniques For Cnc

: "CNC Machining is a process made use of in the production sector that entails the use of computer systems to manage maker tools. Devices that can be managed in this manner consist of lathes, mills, routers as well as grinders.

: The patterns of activity a CNC device adheres to are figured out by the instruction code set in the common CNC language g-code. G-code interacts the complete process for a machining procedure, including rate, feed rate, and also full series of motion.: The CNC machining process is likewise routed in differing ways relying on whether it works on a closed-loop or an open-loop system.

When closed, the control obtains continuous responses from a cyclical loophole. While a CNC maker can run on either system, a closed-loop may be more efficient in dealing with mistakes in the machining procedure as it obtains feedback details on speed, momentum, as well as position.: At BTM, we use several types of machining devices for a comprehensive manufacture approach to making any kind of given part.