For larger commercial makers, the computer is typically an on-board specialized controller. However, for even more enthusiast kinds of machines, or with some retrofits, the computer system can be an external PC. The CNC controller interacts with a collection of electric motors and drive parts to relocate and manage the device axes, carrying out the set movements.

It is also not an automated procedure that imports your CAD model and also spews out the correct NC code. Webcam programming, like 3D modeling, calls for understanding as well as experience in running the program, creating machining methods, as well as recognizing what tools and also procedures to make use of in each circumstance to get the most effective results.

An unique fairly basic machine language that a CNC maker can comprehend and execute. These languages were originally developed to program parts straight at the machine keyboard without the help of a camera program. They inform the machine what relocate to implement, individually, in addition to managing various other maker features such as spindle and also feed speeds, coolant.

Unknown Facts About Cnc Laser Cutter

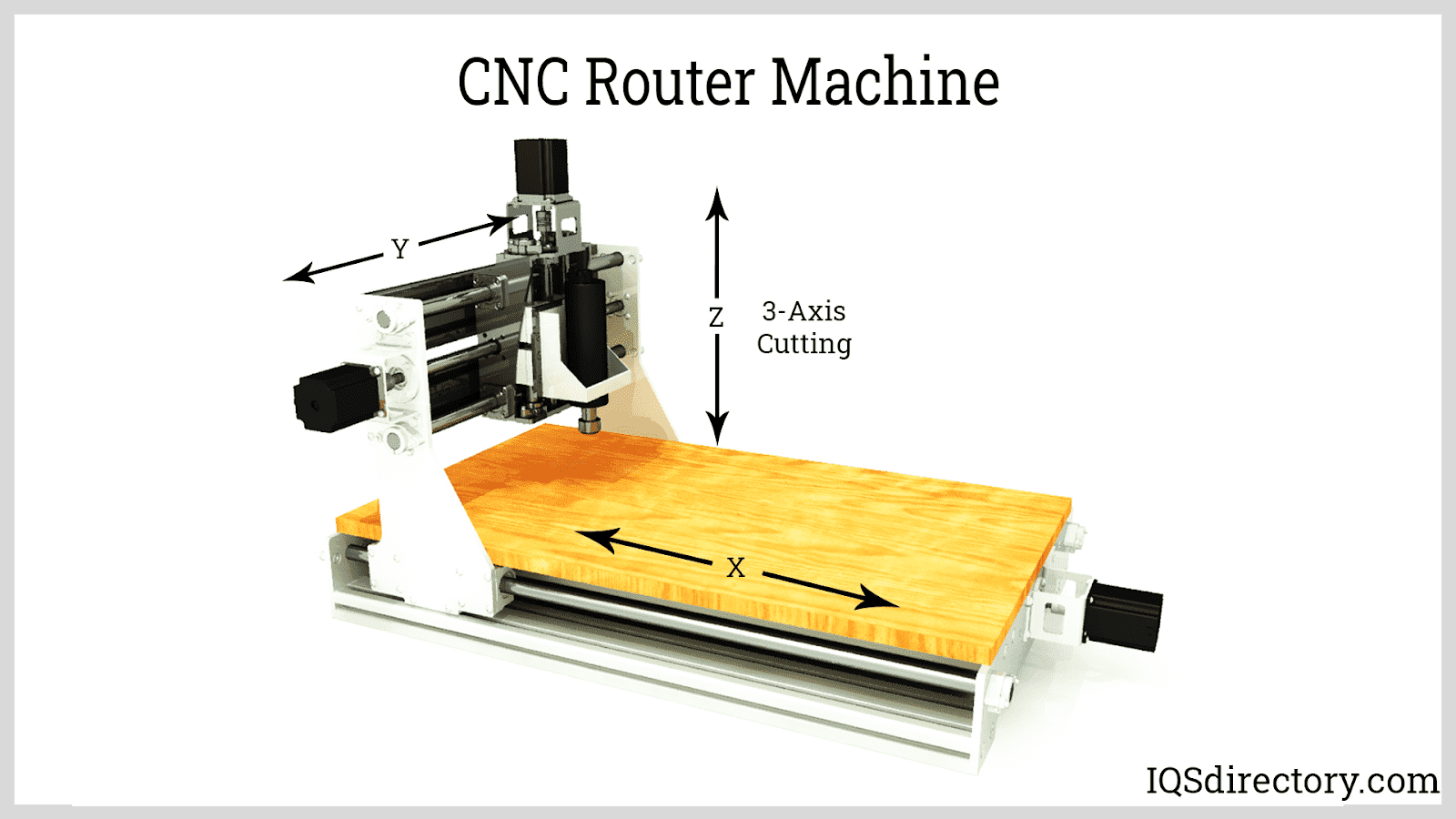

Postprocessors might be free with the webcam system or included price additionals. CNC regulated makers, basic CNC devices can have numerous axes of motion, and these activities can be either linear or rotary. Numerous makers have both kinds. Intermediary equipments like lasers or waterjets generally have simply 2 direct axes, X and also Y.

A five axis milling machine is one that has 3 linear axes and also two rotating, enabling the cutter to run in a complete 180 hemisphere and also in some cases more. Some restrictions of CNC regulated devices Depending on their age and also refinement, CNC makers can be limited to the capacities of their control and drive systems.

In numerous makers, the arcs are restricted to the principal XYZ planes. Rotating axis activities can be taken into consideration like straight movements, just degrees rather than distance. To develop arc movements or linear movements that are at an angle to the primary axes, 2 or even more axes have to interpolate (relocation specifically in an integrated manner) with each other.

Get This Report about Cnc Machine

In the instance of 5 axis machines, all five must be flawlessly synchronized no very easy task. The rate at which the machine controller can receive and also refine the incoming information, transmit commands to the drive system, and check the equipment's rate and placement is critical. Older and also more economical devices are certainly much less qualified in this, a lot similarly that an older computer will certainly function less well and also more slowly (if in any way) as needed jobs than a newer one.

You can think of the first option as a collection of chords on your spline, touching the spline on each end and having a certain variance in the center. Another method is to transform your spline right into a polyline. The fewer sectors you use, the coarser the estimate will certainly be, and also the extra faceted the result.

You can picture that a series of arcs could be able to approximate your spline within tolerance with less, much longer pieces. cnc router. This is the primary reason for preferring arc conversion over easy polyline conversion, particularly if you are functioning with older machines. With more recent ones, there is less of a trouble.

5 Simple Techniques For Cnc Laser

In basic, surfaces are done utilizing all line sections, yet there are scenarios where arcs or a combination of lines as well as arcs can likewise be made use of. The dimension and also number of sectors are determined by the accuracy needed and the technique chosen, and will directly influence the implementation. A lot of brief segments will choke some older equipments, as well as as well couple of will certainly make a faceted part.

With a proficient operator that understands what the customer requires as well as the equipment can deal with, it is usually no worry. Yet some camera systems might not deal with splines or certain kinds of surfaces, so you may need to transform the entities in the CAD software program first (Rhino) before entering into webcam.

Common conventions utilized in defining CNC treatments Your task can be: if all the cutting takes area in the very same plane. In this situation, the cutter does not have any kind of capability of movement in the Z (upright) plane. Generally the X and also Y axes can interpolate together simultaneously to produce angled lines as well as circular arcs.

The Basic Principles Of Cnc Plasma

In this instance, the cutter can move in the Z (upright) plane to change levels, but not at the same time with the X, Y activities. An exemption might be that the cutter can insert helically, that is, do a circle in X, Y while relocating at the same time in Z to form a helix (for instance in string milling).