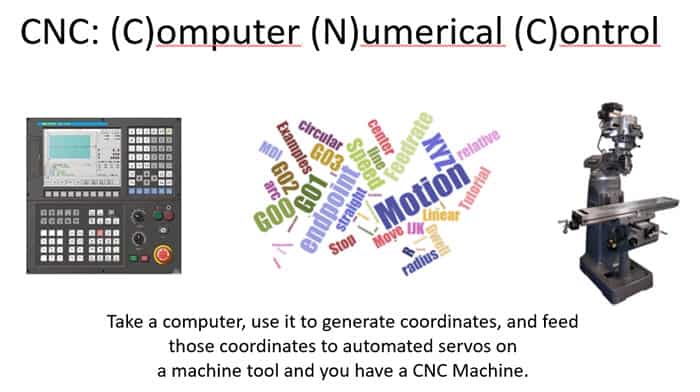

To the sightseer, a CNC system could appear like a regular collection of computer components, yet the software program programs as well as consoles utilized in CNC machining identify it from all other types of computation. If you have an interest in utilizing CNC making to generate different items, figure out more concerning how CNC machining as well as CNC programming functions.

Any offered work surface could necessitate a range of equipment devices, such as drills as well as cutters. In order to suit these demands, a number of today's machines incorporate numerous different functions into one cell. At the same time, a setup could contain a number of equipments and also a collection of robotic hands that move components from one application to an additional, but with everything controlled by the same program.

Lathes In lathe devices, items are cut in a circular direction with indexable tools. With CNC innovation, the cuts used by turrets are brought out with accuracy and also high rate. CNC lathes are utilized to generate complicated designs that would not be feasible on by hand run versions of the equipment. In general, the control functions of CNC-run mills and also turrets are similar.

However, most CNC lathes include 2 axes X as well as Z. Plasma Cutters In a plasma cutter, a plasma torch reduces the material. The process is primary put on metal materials however can likewise be employed on various other surfaces. In order to produce the rate and warm required to cut steel, plasma is produced through a combination of compressed-air gas and also electric arcs.

With EDM, present discharges take place between 2 electrodes, and this removes sections of a provided work surface. When the room in between the electrodes becomes smaller, the electrical area comes to be more extreme and also hence more powerful than the dielectric. This makes it feasible for an existing to pass in between both electrodes. Sections of a workpiece are gotten rid of by each electrode.

Cnc Lathe Machine – An Overview

Companies usually shape manufacturing facility equipment components via this procedure. Water jets are used as a cooler alternative for products that are not able to bear the heat-intensive procedures of various other CNC machines.

What Else Can a CNC Maker Do? As lots of CNC machine video demos have actually revealed, business make use of CNC equipments to make highly detailed eliminate of metal pieces for commercial hardware items. In enhancement to the previously mentioned machines, you can find numerous various other typical pieces of equipment made use of in CNC manufacturing to generate very described and accurate CNC products.

This short article will certainly talk about the most common types: lathes and also milling devices. History, Although wood-working turrets have actually remained in use considering that Scriptural times, the initial practical metalworking turret was created in 1800 by Henry Maudslay. It was just a maker device that held the piece of product being functioned, or work surface, in a clamp, or pin, and rotated it so a cutting tool could machine the surface area to the wanted shape.

Dimensional accuracy was regulated by the driver who observed the finished dials on the handwheels and moved the reducing tool the appropriate amount. Each component that was produced called for the driver to duplicate the motions in the same sequence and to the very same measurements. The very first milling equipment was operated in much the same manner, other than the cutting tool was placed in the rotating spindle.

The movements that are utilized in device tools are called "axis," as well as are referred to as "X" (normally left to right), "Y" (typically front to back), and also "Z" (up and down). The work-table may additionally be turned in the horizontal or upright plane, creating a 4th axis of activity.

The 25-Second Trick For Cnc Laser

Among the troubles with these very early machines was that they required the driver to control the handwheels to make each part. Besides being monotonous and also physically laborious job, the capacity of the driver to make similar components was restricted. Small distinctions in procedure led to variant of the axis dimensions, which, in turn, created inadequately fitting or pointless parts.

As production amounts enhanced, the variety of useful components generated per driver each day were no more economical. What was required was a method to run the activities of the device instantly. Early tries to "automate" these operations utilized a collection of cams that relocated the devices or worktable with linkages.