This kind of lathe machine training can include courses on: Identifying where edits are required from comparing sample components to their specifications CNC shows modifies Creating numerous cycles of test components to improve the results of edits Managing coolant flow, cleaning up the lathe, and fixing and substitute of tools Various other CNC Machining Operations Other mechanical CNC machining procedures include: CNC Machining Equipment and also Components As indicated over, there is a vast array of machining operations offered.

Some software applications have integrated all of the facets of CAD, WEB CAM, and CAE software application. This incorporated program, typically referred to as CAD/CAM/CAE software, allows a solitary software application program to take care of the entire fabrication procedure from style to evaluation to production. What is a CNC Maker?

g., large or hefty componentspresent higher challenges than others. Table 1, below, describes several of the obstacles of machining big parts and heavy components. Keep in mind: Some of the huge part machining and heavy part machining obstacles are provided by Technox Maker & Production Inc. Large Component Requires specific devices for placing and also refining Requires operator training for specific tools A lot more complicated equipment set up May be also big for workplace Amplification of aspects impacting precision Larger quantities of warmth produced during the process Greater opportunity of stress-related distortion Hefty Part Requires specialized tooling as well as equipment for handling and processing Needs driver training for customized devices May be as well hefty for workplace Greater quantity of anxiety on the tools Alternatives to Using a CNC Device Although CNC machining demonstrates benefits over other making processes, it might not be ideal for every single production application, as well as various other procedures might show extra suitable and also cost-efficient.

Have your CNC machines been acting oddly lately? Do you discover an unusual tick in their outcome, or in the way the devices are acting? If so, you're in the appropriate location. We're mosting likely to speak about a few of the most usual issues in CNC makers, and also how to take care of these issues.

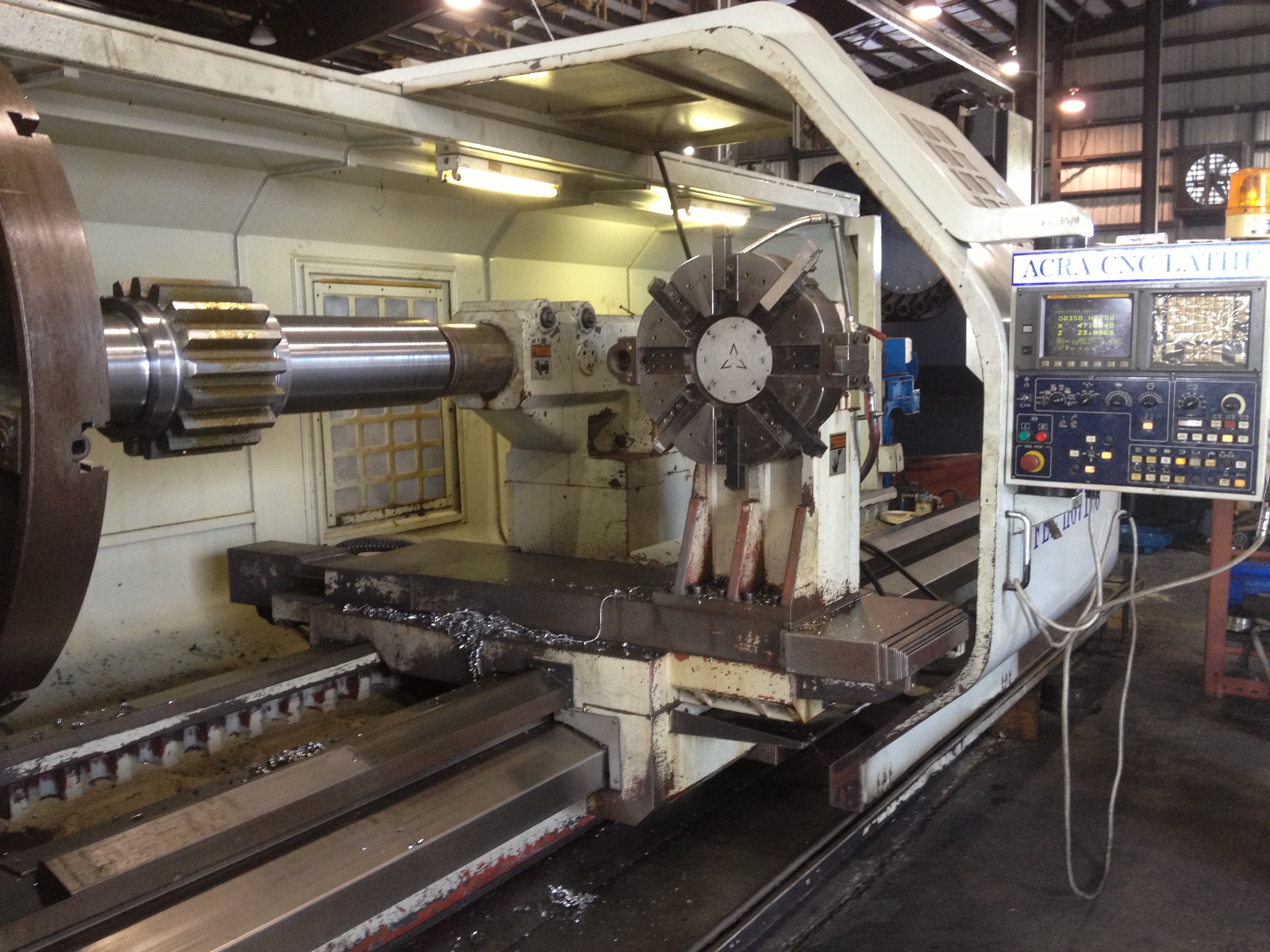

What Is a CNC Equipment? Just How Does CNC Machining Job? What Causes Issues in CNC Machines? Fixing Tips What Is a CNC Maker? A CNC equipment is an electro-mechanical gadget utilized to manipulate as well as control machine-shop devices as well as devices using computer programs. In other words, controllers program the CNC equipment to inform the device shop devices what to do.

The CNC equipment does this by informing the device store device precisely how to relocate, and specifically what pieces of the product to remove, to eventually arrive at the desired outcome. It has several resemblances with 3D printing, in that a computer supplies digital guidelines to devices that after that work to create a finished product.

The Greatest Guide To Wood Cnc Machine

They create issues and require maintenance just like any type of various other kind of equipment or device. As well as like any various other device, there are certain points you can do that could accidentally harm these makers.

Poor or Improper Maintenance CNC devices need to be carefully cleaned and lubed on a routine basis or else, problems can begin to occur. This might appear to be simply a hygiene problem, but it can have real ramifications in the maker's outcome.

If this problem remains to go unchecked, it will develop obstacles as the equipment has a hard time to situate as well as hold products still. This results in better issues with accuracy as well as accuracy, and also eventually brings about extra mistakes. Inappropriate lubrication can lead to equipment parts sticking or not relocating as smoothly as they should.

Both getting too hot and also a lack of air can additionally cause issues like material activity during the procedure. Improper Setups or Devices Maybe one of your devices is ending up being candid, a cutting coolant or lube is falling short to work appropriately or a device is relocating at the wrong rate. All these concerns will trigger similar type of issues.

The reason for this is basic. If the device is relocating too slowly, the product will certainly be under the reducing side for longer than it ought to be. This causes the burning and scarring you're seeing. If the coolant is not functioning properly, points can be obtaining as well hot, and the sides of the product might be obtaining singed as an outcome.