Bolting the bollscrews3 The devices that move the bed or pin are called ballscrews. These change rotating activity of the drive motors into direct motion as well as are composed of a screw shaft and support bearings. As the shaft turns, a bearing install follows the spiral grooves in the shaft and also generates a really accurate straight activity that moves either the worktable under the spindle, or the spindle provider itself.

Mounting the spindle4 The spindle is machined as well as ground, placed to its drive motor, and afterwards bolted to the movable spindle carrier. Each axis of motion has a different ballscrew and also collection of means in a lot of machining. The controller5 The computer system, or controller, is a digital setting up separate from the remainder of the maker.

On the front panel are the information entrance tricks, information link ports, and start-stop buttons. 6 The constructed maker is examination run for accuracy. Each device has slight physical distinctions that are mathematically corrected in the computer os. These improvement worths are saved in a separate memory, and the equipment checks these continuously.

After screening, the ended up device is repainted and planned for shipment. Quality Assurance, High quality in a machining facility need to be constructed in from the style with distribution and set-up. Mindful direction to the operators is also crucial to avoid a crash, the unintended collision of the collaborate with the device.

One suggestion under growth is a spider-like device whose pin is put on hold by six telescoping ballscrew shows off. The struts resemble the means in a traditional maker, yet they are rounded with the ballscrew setting up in the facility. The motions of the pin are controlled by an advanced computer system executing numerous calculations to guarantee correct part shape.

This will not come cheaply, as well as the price of advanced CNC makers will certainly be beyond the reach of many companies. It will, how-ever, decrease the costs of the standard CNC equipments doing the original three-axis motions.

More About Cnc Router

The first NC makers were developed in the 40s as well as 50s. These equipments based on existing devices but with some alterations.

The configuration depends on the geometry of the component as well as the offered machinery and also tooling. Nesting implies the alignment and also placement of parts loved one to raw material.

G-code refers to a language that is utilized to inform a machine just how to relocate. The instructions are fed to a machine controller which is simply an industrial computer.

And the motors, certainly, identify the course to be followed. The M-code, on the various other hand, provides all the info that the G-code overlooks. That's why it is called either. M-code's guidelines consist of info concerning using coolant, device modification, program quits, and so on. Both are similarly crucial yet not the same.

Not all these machines are used for CNC machining. We will certainly take a closer look at all the different kinds of CNC equipments that are offered a little later., CNC machining refers to only a few of these automated processes.

Transforming is rather a lot the reverse of milling. Is typically made use of for generating shafts. The device is brought versus the revolving workpiece to cut off little bits of steel, understood as chips or swarf.

Examine This Report about Cnc Lathe

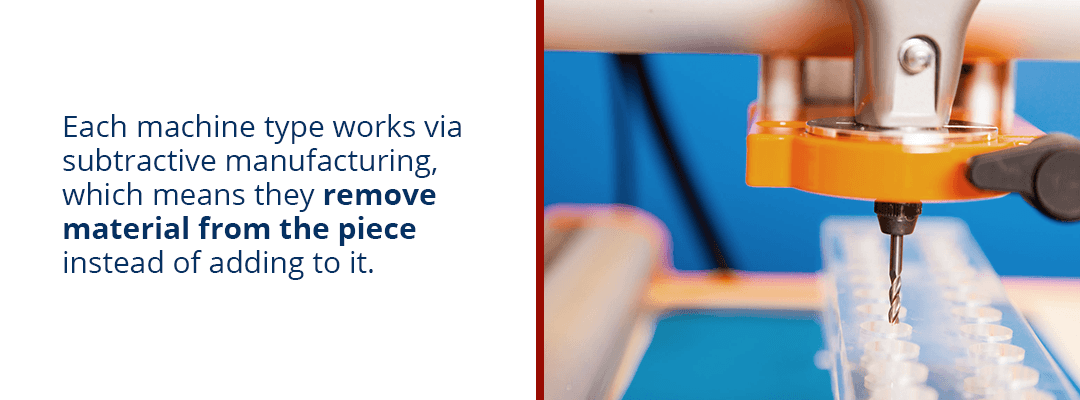

Transmitting CNC routers are apparently comparable to CNC milling makers. Below also the rotating piece is the reducing head. The primary distinction lies with the materials appropriate for cutting. Routers are an excellent suitable for reducing softer products (not metals) that do not need very high accuracy. The factor for that is its lesser outcome power.